Product Benefits

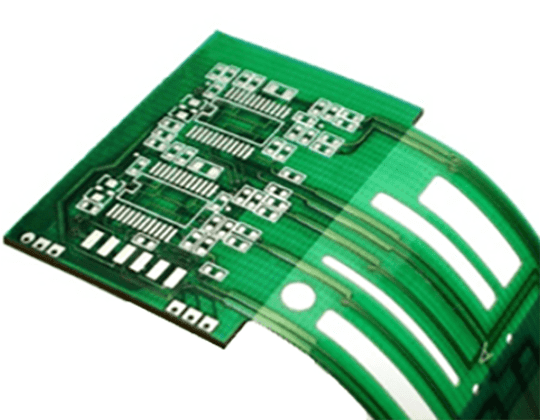

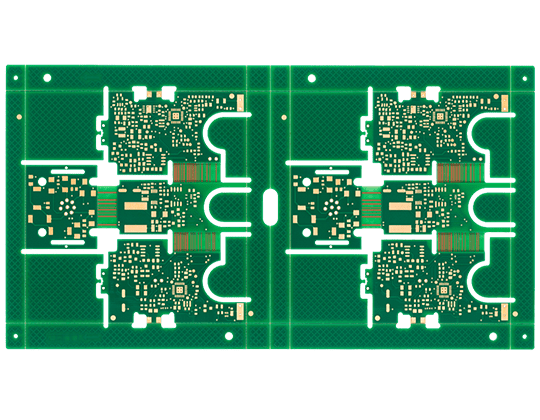

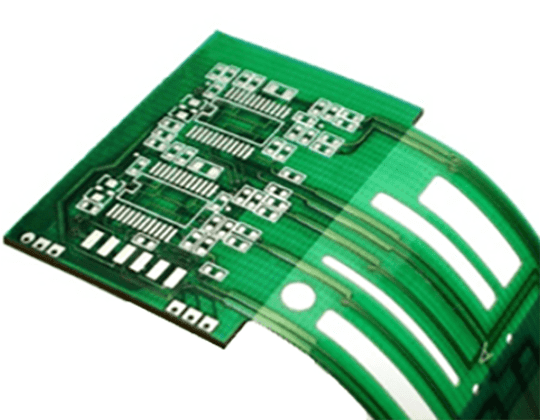

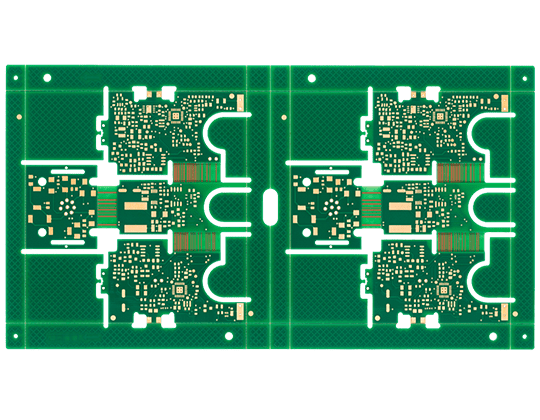

Semi-Flex PCBs are a cost-efficient solution to optimize a great number of projects. Made from FR4 material, which is the most affordable base material for PCBs, it can reduce space, weight, and improve the reliability of the final product as connectors are considered a reliability risk in many applications.

Size Optimization

Using FR4 Semi-Flex optimizes the PCB size, saving the space of the connectors on both “rigid” parts.

Cost-Effective

The FR4 Semi-Flex replaces 2 or more PCBs, simplifies the assembly process, eliminates connectors, and is cheaper than the Rigid-Flex solution.

Time Saving

FR4 Semi-Flex reduces the time needed for design, procurement, and assembly.

Reliability and Durability

Fewer solder joints and fewer connectors.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

A semi-flex PCB is characterized by its ability to bend or flex to a certain degree while maintaining its structural integrity. This type of PCB is often used to save space in the final product and avoid the use of connectors between two circuit boards. Semi-flex PCBs are manufactured using a combination of traditional PCB fabrication processes, such as photolithography, etching, and drilling, as well as specialized techniques for handling the flexible substrate. The final product is a PCB that can bend or flex to a certain degree while maintaining its electrical performance and durability.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Base Material: The base material used in a semi-flex PCB is FR4.

Flexible Area: The flexibility is created either by Z-milling the flex area in the FR4 or by sequential stack-up. The thin FR4 area allows a certain degree of static flexibility, with less than 10 bending cycles.

Lines and Spaces: There are restrictions to minimum trace and spacing widths in the semi-flexible area to ensure trace strength and reliability.

Layer Count: There are no restrictions to the total layer count in an FR4 Semi-Flex PCB, but the flexible part can only hold a maximum of 2 layers.

Surface Finish: All common surface finishes are supported on FR4 Semi-Flex

Solder Mask: The solder mask in the flexible area needs to be either a flexible solder mask or a PI coverlay. Other parts of the circuit board can have a standard liquid solder mask.

Flexible Area: The flexibility is created either by Z-milling the flex area in the FR4 or by sequential stack-up. The thin FR4 area allows a certain degree of static flexibility, with less than 10 bending cycles.

Lines and Spaces: There are restrictions to minimum trace and spacing widths in the semi-flexible area to ensure trace strength and reliability.

Layer Count: There are no restrictions to the total layer count in an FR4 Semi-Flex PCB, but the flexible part can only hold a maximum of 2 layers.

Surface Finish: All common surface finishes are supported on FR4 Semi-Flex

Solder Mask: The solder mask in the flexible area needs to be either a flexible solder mask or a PI coverlay. Other parts of the circuit board can have a standard liquid solder mask.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

FR4 Semi-Flex is a cheaper solution than Rigid-Flex. It should not be used for applications exposed to shock and vibrations. FR4 Semi-Flex creates reliable 3D connectivity opportunities by replacing board-to-board connectors, which leads to space and weight reductions. It is widely used in Instrumentation, Metering, Sensor technology, and Industrial controls.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

A semi-flex PCB is characterized by its ability to bend or flex to a certain degree while maintaining its structural integrity. This type of PCB is often used to save space in the final product and avoid the use of connectors between two circuit boards. Semi-flex PCBs are manufactured using a combination of traditional PCB fabrication processes, such as photolithography, etching, and drilling, as well as specialized techniques for handling the flexible substrate. The final product is a PCB that can bend or flex to a certain degree while maintaining its electrical performance and durability.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Base Material: The base material used in a semi-flex PCB is FR4.

Flexible Area: The flexibility is created either by Z-milling the flex area in the FR4 or by sequential stack-up. The thin FR4 area allows a certain degree of static flexibility, with less than 10 bending cycles.

Lines and Spaces: There are restrictions to minimum trace and spacing widths in the semi-flexible area to ensure trace strength and reliability.

Layer Count: There are no restrictions to the total layer count in an FR4 Semi-Flex PCB, but the flexible part can only hold a maximum of 2 layers.

Surface Finish: All common surface finishes are supported on FR4 Semi-Flex

Solder Mask: The solder mask in the flexible area needs to be either a flexible solder mask or a PI coverlay. Other parts of the circuit board can have a standard liquid solder mask.

Flexible Area: The flexibility is created either by Z-milling the flex area in the FR4 or by sequential stack-up. The thin FR4 area allows a certain degree of static flexibility, with less than 10 bending cycles.

Lines and Spaces: There are restrictions to minimum trace and spacing widths in the semi-flexible area to ensure trace strength and reliability.

Layer Count: There are no restrictions to the total layer count in an FR4 Semi-Flex PCB, but the flexible part can only hold a maximum of 2 layers.

Surface Finish: All common surface finishes are supported on FR4 Semi-Flex

Solder Mask: The solder mask in the flexible area needs to be either a flexible solder mask or a PI coverlay. Other parts of the circuit board can have a standard liquid solder mask.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

FR4 Semi-Flex is a cheaper solution than Rigid-Flex. It should not be used for applications exposed to shock and vibrations. FR4 Semi-Flex creates reliable 3D connectivity opportunities by replacing board-to-board connectors, which leads to space and weight reductions. It is widely used in Instrumentation, Metering, Sensor technology, and Industrial controls.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Industries

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Industries

Metering

With ultra-modern laboratories and equipment, ICPRUS guarantees long product life and high quality.

Automotive

Top Automotive brands choose ICPRUS to match and exceed the high quality and logistics demands of their industry.

Medical

An ever-increasing amount of companies in the medical industry rely on the Precision from ICPRUS.

Industry

The Industrial Automation sector benefits from ICPRUS’s intimate understanding of the complexity of automation and robotics.

Consumer &

Multimedia

Multimedia

The Industrial Automation sector benefits from ICPRUS’s intimate understanding of the complexity of automation and robotics.

Aerospace

ICPRUS is growing in the aerospace industry because of the benefits offered by our expert services and one-stop solutions.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Technical Data

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Technical Data

Do you have any questions? Contact us!