Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Product Benefits

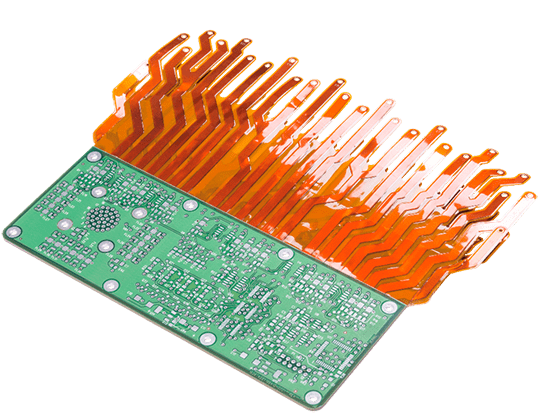

Rigid-Flex makes board-to-board connectors and cables redundant, which saves space and weight. It can endure vibration and shock, which makes it superior for a wide range of products. The rigid parts ensure good component support, while the flexible parts make it possible to integrate several rigid PCBs into one robust solution, with excellent signal integrity.

Flexibility

PI core laminate and coverlay materials have different glue system properties dedicated to supporting the specific construction, whether it is a dynamic or static solution you are seeking.

Cost-Effective

Rigid Flex enables you to minimize the overall PCB size, replaces the board-to-board connectors, and reduces the number of assembly processes. This creates considerable logistics savings.

Weight Reduction

Rigid-Flex offers considerable weight and space savings compared to connector-cabled rigid PCBs.

Reliability and Durability

Reliability is increased by eliminating the use of cables and connectors.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

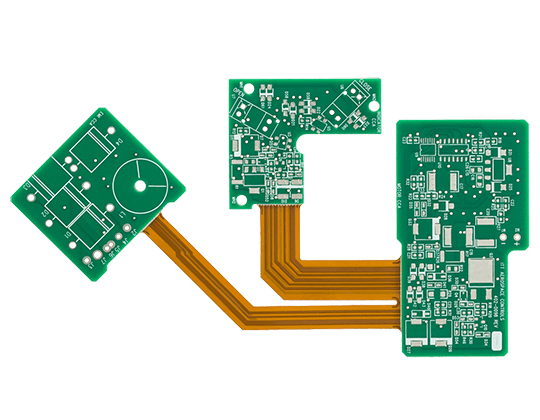

Rigid-flex PCBs combine the benefits of both rigid and flexible PCBs. The rigid parts of the PCB interconnect through flexible PI Kapton layers. The rigid material provides structural support for the components. The PI Kapton enables bendability for both static and dynamic flexible solutions.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Base Material: The most common material choice for the rigid layers is FR4, but other rigid materials like woven glass Polyimide can also be used.

Flexible Area: The flexible area is made of PI Kapton Polyimide material. The Cu is glued to the PI core material using mainly Acrylic or Polyimide adhesive (also called adhesive less).

Lines and spaces: Standard 100um minimum, advance down to 30um.

Vias: Rigid-Flex can contain PTH, blind vias, buried vias and Laser drilled micro-vias.

Layer Count: Up to24 layers

Surface Finish: ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling)

Solder Mask: Liquid photo imageable Solder mask can be used in rigid areas. PI Coverlay or Flexible solder mask lacquer can be used in the flexible areas.

Flexible Area: The flexible area is made of PI Kapton Polyimide material. The Cu is glued to the PI core material using mainly Acrylic or Polyimide adhesive (also called adhesive less).

Lines and spaces: Standard 100um minimum, advance down to 30um.

Vias: Rigid-Flex can contain PTH, blind vias, buried vias and Laser drilled micro-vias.

Layer Count: Up to24 layers

Surface Finish: ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling)

Solder Mask: Liquid photo imageable Solder mask can be used in rigid areas. PI Coverlay or Flexible solder mask lacquer can be used in the flexible areas.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

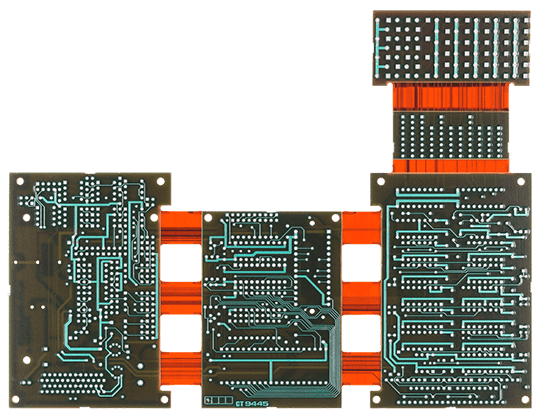

Rigid-Flex stack-up can contain 2 to 24 layers. The stack-up configurations are nearly limitless and can be built with PTHs, blind vias, buried vias, and laser drilled micro-vias.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Rigid Flex PCBs are used in almost every industry that needs space and weight reductions such as automotive, wearable devices, laptops, phones, medical, military, instrumentation, avionics, sensors, and industrial controls.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Rigid-flex PCBs combine the benefits of both rigid and flexible PCBs. The rigid parts of the PCB interconnect through flexible PI Kapton layers. The rigid material provides structural support for the components. The PI Kapton enables bendability for both static and dynamic flexible solutions.

Base Material: The most common material choice for the rigid layers is FR4, but other rigid materials like woven glass Polyimide can also be used.

Flexible Area: The flexible area is made of PI Kapton Polyimide material. The Cu is glued to the PI core material using mainly Acrylic or Polyimide adhesive (also called adhesive less).

Lines and spaces: Standard 100um minimum, advance down to 30um.

Vias: Rigid-Flex can contain PTH, blind vias, buried vias and Laser drilled micro-vias.

Layer Count: Up to24 layers

Surface Finish: ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling)

Solder Mask: Liquid photo imageable Solder mask can be used in rigid areas. PI Coverlay or Flexible solder mask lacquer can be used in the flexible areas.

Flexible Area: The flexible area is made of PI Kapton Polyimide material. The Cu is glued to the PI core material using mainly Acrylic or Polyimide adhesive (also called adhesive less).

Lines and spaces: Standard 100um minimum, advance down to 30um.

Vias: Rigid-Flex can contain PTH, blind vias, buried vias and Laser drilled micro-vias.

Layer Count: Up to24 layers

Surface Finish: ENIG (Electroless Nickel Immersion Gold) or HASL (Hot Air Solder Leveling)

Solder Mask: Liquid photo imageable Solder mask can be used in rigid areas. PI Coverlay or Flexible solder mask lacquer can be used in the flexible areas.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Rigid-Flex stack-up can contain 2 to 24 layers. The stack-up configurations are nearly limitless and can be built with PTHs, blind vias, buried vias, and laser drilled micro-vias.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Rigid Flex PCBs are used in almost every industry that needs space and weight reductions such as automotive, wearable devices, laptops, phones, medical, military, instrumentation, avionics, sensors, and industrial controls.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Industries

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Industries

Automotive

Top Automotive brands choose ICPRUS to match and exceed the high quality and logistics demands of their industry.

Medical

An ever-increasing amount of companies in the medical industry rely on the Precision from ICPRUS.

Industry

The Industrial Automation sector benefits from ICPRUS’s intimate understanding of the complexity of automation and robotics.

Consumer &

Multimedia

Multimedia

The Industrial Automation sector benefits from ICPRUS’s intimate understanding of the complexity of automation and robotics.

Aerospace

ICPRUS is growing in the aerospace industry because of the benefits offered by our expert services and one-stop solutions.

Metering

With ultra-modern laboratories and equipment, ICPRUS guarantees long product life and high quality.

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Technical Data

Aratek biometric solutions

streamlines identity

management for millions

streamlines identity

management for millions

Technical Data

Do you have any questions? Contact us!