Product Benefits

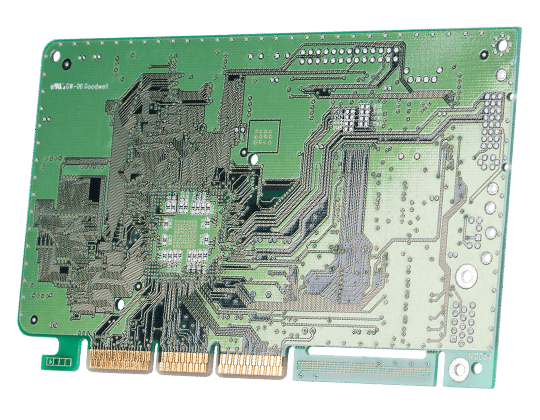

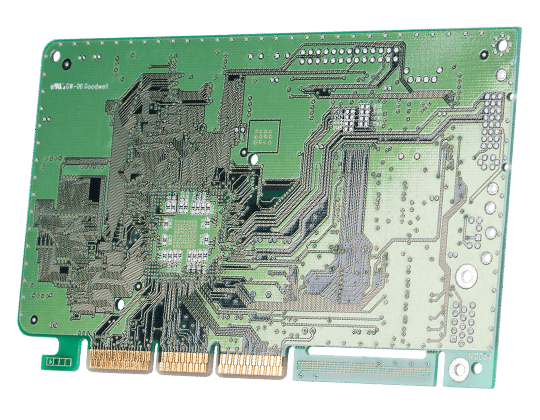

DS and Multilayer PCBs contain plated through holes enabling signals to cross through the layers. It makes higher component density possible compared with single-sided technology. It is a well-known technology used in all kinds of electronic devices.

Better Signal Integrity

DS containing both signal and ground plane layers enable better signal integrity since traces can be impedance controlled with reference in ground plane layers.

Cost-Effective

FR4 is the most cost-effective PCB material for DS PCB on the market.

High Reliability

Allow a reduction of 50% of the size of the board compared to a single-sided PCB.

FR4 is glass-reinforced epoxy laminate. The designation FR4 was created by NEMA in 1968 (National Electrical Manufacturers Association). FR is the short form of Flame Retardant. FR4 is offered in many variations with modification of the epoxy to create lower CTE, higher Tg., higher CTI, lower Df & Dk etc…

PCB Materials: Tg. 130 to 180C°, CTE 40/220 to 60/300ppm, halogen free optionally.

Copper Weight: 1 oz/ft² minimum

Lines and Spaces: low cost 150um, standard 100um, advanced 75um

Vias: Standard 0,3mm, min. 0,15mm

Layer Count: 2-64 layers.

Surface Finish: LF HASL, OSP, Im Tin, Im Silver, ENIG, ENEPIG and Hard or Soft Gold.

Solder Mask: Green, White, Black, Blue, Red, Yellow.

Copper Weight: 1 oz/ft² minimum

Lines and Spaces: low cost 150um, standard 100um, advanced 75um

Vias: Standard 0,3mm, min. 0,15mm

Layer Count: 2-64 layers.

Surface Finish: LF HASL, OSP, Im Tin, Im Silver, ENIG, ENEPIG and Hard or Soft Gold.

Solder Mask: Green, White, Black, Blue, Red, Yellow.

Double-sided PCBs are commonly used in a wide range of electronic applications such as telecommunications, industrial control systems, and power supplies. They are also used in prototyping and small-scale production runs.

FR4 is glass-reinforced epoxy laminate. The designation FR4 was created by NEMA in 1968 (National Electrical Manufacturers Association). FR is the short form of Flame Retardant. FR4 is offered in many variations with modification of the epoxy to create lower CTE, higher Tg., higher CTI, lower Df & Dk etc…

PCB Materials: Tg. 130 to 180C°, CTE 40/220 to 60/300ppm, halogen free optionally.

Copper Weight: 1 oz/ft² minimum

Lines and Spaces: low cost 150um, standard 100um, advanced 75um

Vias: Standard 0,3mm, min. 0,15mm

Layer Count: 2-64 layers.

Surface Finish: LF HASL, OSP, Im Tin, Im Silver, ENIG, ENEPIG and Hard or Soft Gold.

Solder Mask: Green, White, Black, Blue, Red, Yellow.

Copper Weight: 1 oz/ft² minimum

Lines and Spaces: low cost 150um, standard 100um, advanced 75um

Vias: Standard 0,3mm, min. 0,15mm

Layer Count: 2-64 layers.

Surface Finish: LF HASL, OSP, Im Tin, Im Silver, ENIG, ENEPIG and Hard or Soft Gold.

Solder Mask: Green, White, Black, Blue, Red, Yellow.

Double-sided PCBs are commonly used in a wide range of electronic applications such as telecommunications, industrial control systems, and power supplies. They are also used in prototyping and small-scale production runs.

Industries

Industries

Automotive

Top Automotive brands choose ICPRUS to match and exceed the high quality and logistics demands of their industry.

Medical

An ever-increasing amount of companies in the medical industry rely on the Precision from ICPRUS.

Industry

The Industrial Automation sector benefits from ICPRUS’s intimate understanding of the complexity of automation and robotics.

Consumer &

Multimedia

Multimedia

The Industrial Automation sector benefits from ICPRUS’s intimate understanding of the complexity of automation and robotics.

Aerospace

ICPRUS is growing in the aerospace industry because of the benefits offered by our expert services and one-stop solutions.

Metering

With ultra-modern laboratories and equipment, ICPRUS guarantees long product life and high quality.

Technical Data

Technical Data

Do you have any questions? Contact us!